Considering the choice of glass material or polycarbonate roofing to make the light roof is always a challenge for architects and consulting units. Depending on the specific requirements of each project, architects will offer practical solutions. With the purpose of clearly distinguishing the advantages and disadvantages of each material through a comparison of some criteria, E-Power hopes to bring valuable suggestions for architects and consulting units as follows:

1. In terms of transparency and UV protection:

Glass allows up to 98% of light to pass through. This is a feature that makes many customers want to choose the product. However, in fact, the climate in Vietnam is tropical, with a lot of sunshine and the sun with UVA and UVB damage the skin, the light intensity is quite large, the transmitted heat is also large, so it is necessary to limit the use of UVA and UVB. use transparent glass.

With the interior space, when using non-standard glass, it will cause a greenhouse effect, causing the air to become stuffy, difficult to breathe, a lot of heat absorbed inside. When using, experts need to carefully calculate the amount of heat and light before installing

2. Weight Criteria:

Glass is many times heavier than polycacbonate: due to the structure of glass, 1m3 of glass has the same weight as 1m3 of concrete, so the same thickness, glass products will be at least 2 times heavier than Polycacbonate. With such light weight, the transportation and construction of polycacbonate will be much more favorable than glass.

3. Sheet size:

The largest available glass sizes are: 3500 x 7498 for flat glass and 3000 x 6000 for curved glass.

Solid polycacbonate sheets can reach size: 2450 x 3050mm, and hollow polycacbonate sheets will be 600 * 11800mm.

For the same construction area, the bonding between the glass panels will require 3-4 times the construction time of the glass compared to polycacbonate

.

4. Bearing capacity:

Glass is quite hard and brittle, in the process of production, transportation and construction, special attention must be paid to it because it is easy to break the glass. During the construction process, special attention must be paid to the heavy plate, to ensure that the edges are always observed and tighten screws, bolts just enough. Parts in contact with other materials such as aluminum, steel need glue or rubber gasket to ensure safety.

Polycacbonate is plastic products, solid structure and 200 times impact resistance than normal glass. It is for that reason that Polycacbonate is trusted in many glass roofs, large-format halls, areas with complex terrain, much affected by storms ... or unstable seismic, near easy areas is shaken slightly.

5. Durability:

Under ideal conditions, glass is more durable than polycacbonate. A properly manufactured glass sheet has a durability of 30-50 years. There is a polycacbonate plastic sheet that has a durability of 20-25 years depending on location and purpose of use.

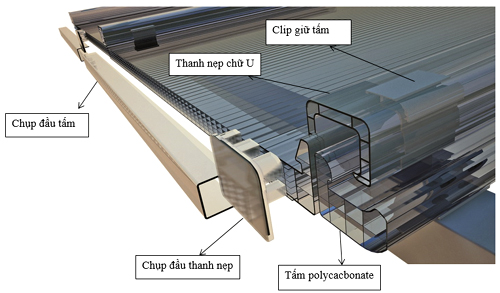

6. Links between plates

Since the glass is quite brittle, the bending and shaping of the glass is very limited. Polycacbonate is product derived from primary plastic and has very good flexural and tensile ability. Taking advantage of this feature, European advanced manufacturing technology (Germany) has designed components to prevent water from entering without the use of screws and silicone glue, ensuring resistance to wind and wind. weather resistant products. This is considered to be the biggest competitive advantage of polycarbonate over glass.

Thus, based on the purpose of use, the aesthetic requirements, the durability that the design consultant unit, architects can consider using glass or polycacbonate plastic accordingly. If you need advice, please contact us by phone 0964 284 422 or visit www.epower.com.vn for more details.